The Diamond Journey

Few people outside the gem industry realise the true nature of a gemstone’s journey from the mine to our showroom. Tons of earth and countless hours of labour are needed to bring a gem from mine to market.

Hidden Gems

Diamonds lay hidden deep within the Earth for millions of years before being brought to the surface by violent volcanic eruptions. Since magma can dissolve diamonds, not every diamond survived this process. The diamonds that did survive were trapped in their host rock, called kimberlite.

Over time, erosion freed some of these diamond crystals and carried them downstream to where they can be found in alluvial deposits, such as those in streams and rivers. Often, diamonds with many inclusions were shattered during this tumbling process.

Diamond Mining

The way a mineral forms helps determine its identity. Diamonds form under high temperature and pressure conditions only within a specific depth range (about 100 miles) beneath the earth’s surface. A diamond’s crystal structure is isometric, meaning the carbon atoms are bonded in the same way in all directions.

Another mineral, graphite, contains only carbon, but its formation process and crystal structure are very different. The result is that graphite is so soft that you can write with it, while diamond is so hard that you can only scratch it with another diamond.

Without these factors, a diamond might be just another mineral. Fortunately, though, this special combination of chemical composition, crystal structure, and formation process gives diamonds the qualities that make them extraordinary.

.jpg)

Diamond Sorting

Rough diamonds are typically categorised into two main model types: "Sawable" and "Makeable."

Sawable diamonds are often shaped like octahedrons or dodecahedrons. These stones are cut (sawn) before they are polished, resulting in two polished gems.

On the other hand, Makeable diamonds tend to be broken octahedral or dodecahedral shapes or flatter whole models. They generally yield one polished stone after processing.

At the mine, diamonds are sorted into thousands of categories. The sorting process ensures the correct valuation of all mines’ productions. It also ensures that a consistent assortment of diamonds can be delivered. Consistency is ensured using samples that guide decision-making regarding shape, quality, and colour.

-(1).jpg)

Diamond Colour

The most common colours of diamonds range from colourless to yellow and brown. Diamonds described as 'white' are actually colourless and fully transparent. However, rarer colours, such as blue, yellow, pink, red and green, occasionally appear. These rare examples are known as fancy-coloured diamonds. Due to their rarity and beauty, fancy-coloured diamonds are typically worth much more than white diamonds.

DISCOVER.jpg)

Diamond Carat

Carat refers to the weight of a diamond, which is equivalent to 0.2 grams.

Rough diamonds come in various weights as categorised below:

Special Stones: 10.8 carats and above

Large Stones: 1.8 carats – 10.79 carats

Grainers: 0.66 carats – 1.79 carats

Smalls: 0.65 carats & below

.jpg)

Diamond Clarity

The clarity of a diamond refers to the number, size, position, and type of impurities, inclusions, or cracks present within the stone. This factor significantly affects the final value of the diamond and may impact how it is divided into smaller stones prior to polishing.

Inclusions also affect the way light passes through the stone, potentially diminishing the polished diamond's "fire" and brilliance. An inclusion-free, clean stone holds greater value due to its rarity.

-(1).jpg)

Diamond Cutting

A beautifully finished diamond is truly dazzling; every facet showcases the craftsman's skill and attention to detail. Each facet and angle influences the amount of light that is reflected back to the eye, enhancing the diamond's face-up appearance and overall appeal.

In contrast, a rough diamond resembles any transparent crystal or even a piece of broken glass. However, once it is cut into a faceted gemstone, it transforms into a sparkling, shimmering object that is uniquely captivating in appearance.

.jpg)

The manufacturing of gem-quality diamonds has advanced more since 1980 than in the preceding 100 years. During the past two decades, a quiet revolution has taken place in much of the diamond-manufacturing industry.

By adapting computer-imaging techniques, precision measurement systems, lasers, and other modern technological equipment, many manufacturers have improved their ability to cut gem diamonds in ways unimaginable only a few short years before.

In the final stage of diamond cutting, the polisher uses a special tool known as a "tang" to hold the diamond. The diamond is then polished on a Scaife, a metal polishing wheel powered by an electric motor that can reach speeds of up to 4,000 RPM.

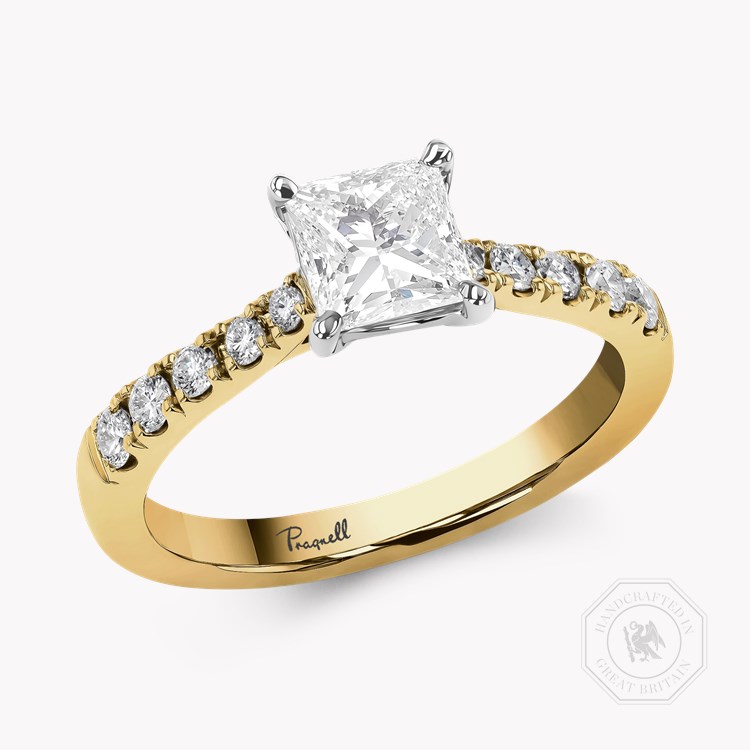

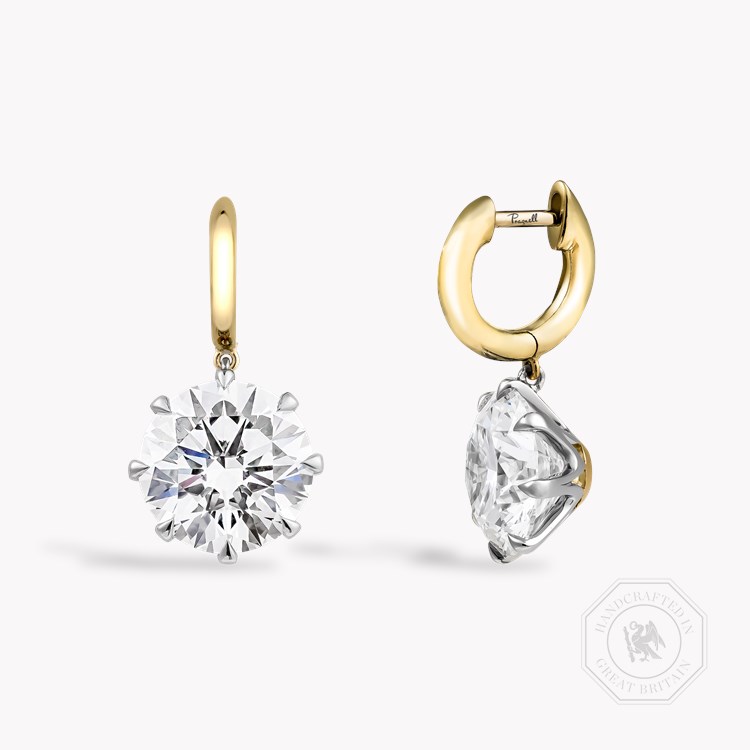

Explore Diamond Jewellery

Jewellery CLP Page

Contact us